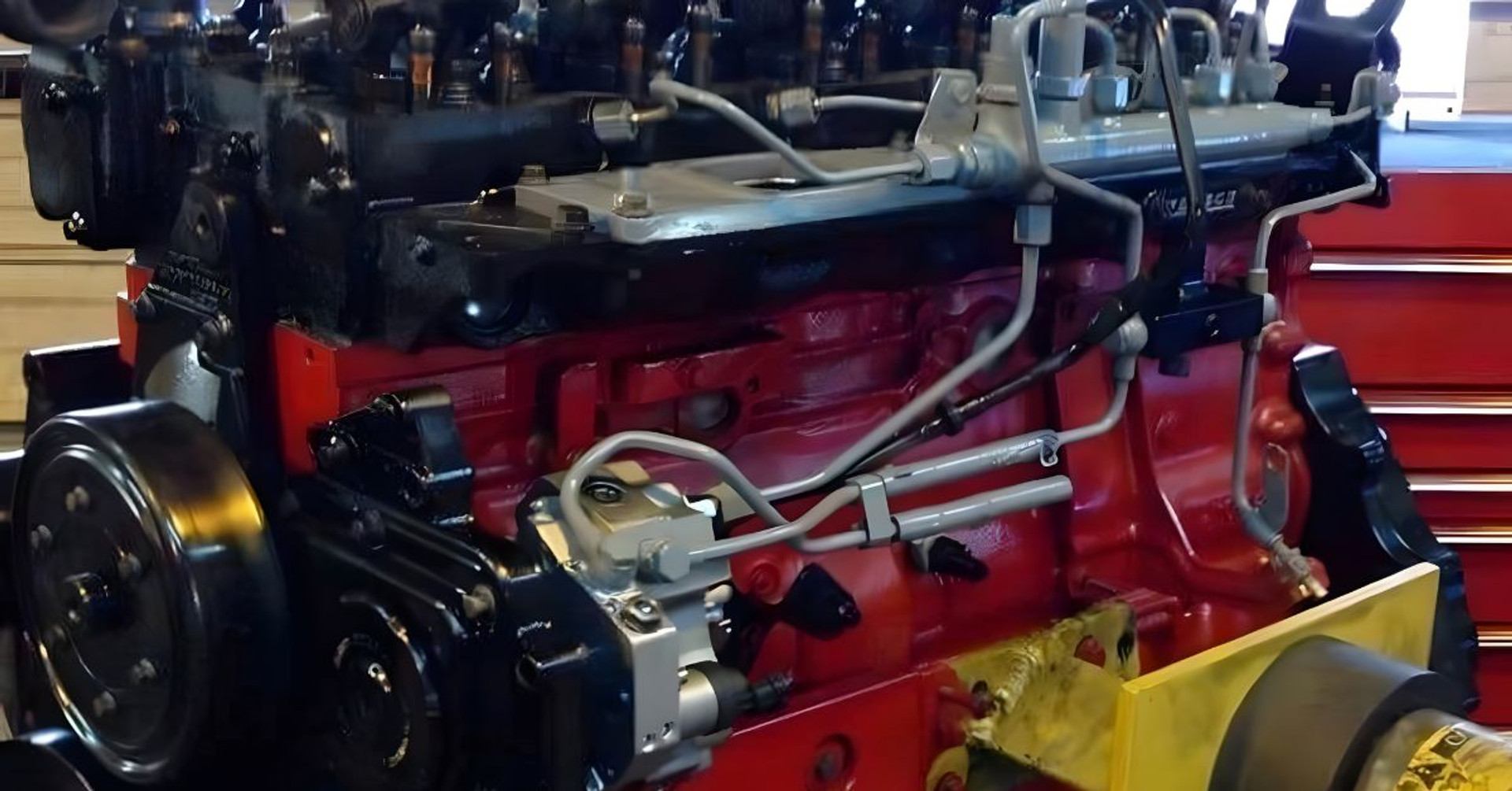

How To Swap Out a 5.9L Cummins Diesel Engine

Estimated 0 min read

Replacing a 5.9L Cummins diesel engine is a daunting task, but with the proper guidance and preparation, it can be a rewarding project for any diesel enthusiast or DIY mechanic. Known for their durability and performance, 5.9L Cummins engines are a favorite choice for heavy-duty applications and swapping one can breathe new life into your vehicle.

Our guide will walk you through the critical steps, tools, and tips you'll need to swap out a 5.9L Cummins diesel engine efficiently and safely. Whether you're upgrading your current setup or replacing a worn-out engine, we've got you covered with practical advice to make the process as smooth as possible. Let's get started!

Understanding the 5.9L Cummins Engine Basics

The 5.9L Cummins diesel engine stands as one of the most reliable and powerful engines ever produced for trucks. This inline-six turbocharged diesel engine powered Dodge Ram trucks from 1989 through 2007, earning legendary status among enthusiasts. The engine produces substantial torque and horsepower while maintaining excellent fuel economy for its size and capability. Understanding these fundamentals helps you appreciate why this engine swap remains popular among diesel performance enthusiasts today.

Preparing Your Workspace and Tools

Creating a proper workspace ensures your engine swap proceeds smoothly and safely throughout the entire process. You need a level concrete surface, adequate lighting, and sufficient space to maneuver around your vehicle comfortably. Essential tools include engine hoists, transmission jacks, socket sets, wrenches, and specialty diesel engine tools for specific components. Safety equipment like jack stands, wheel chocks, and protective gear protects you during the demanding physical work ahead.

Removing the Old Engine Safely

Engine removal requires methodical disconnection of all systems before lifting the powerplant from the engine bay. Start by draining all fluids, including coolant, oil, and fuel, to prevent spills during the removal process. Disconnect the battery, remove the hood, and systematically label every electrical connection, vacuum line, and fuel line. Remove the radiator, cooling fans, and air intake components to create adequate clearance to extract the engine.

Disconnecting Electrical and Fuel Systems

The 5.9L Cummins features complex electrical systems that require careful attention during disconnection and reconnection phases. Remove the engine control module connections, alternator wiring, starter cables, and all sensor connections throughout the engine. Disconnecting the fuel system involves the high-pressure fuel lines, return lines, and fuel filter connections that supply the injection system. Document each connection with photos or labels to ensure proper reassembly when installing your replacement engine.

Transmission and Drivetrain Considerations

Your transmission compatibility directly affects the success and performance of your 5.9L Cummins engine swap project. The engine mates with various automatic and manual transmissions, each requiring specific bellhousing patterns and torque converter configurations. Consider whether your existing transmission can handle the increased torque output of the Cummins diesel engine. Upgrading transmission components or selecting a different transmission may prove necessary for optimal performance and reliability.

Buying Your Replacement 5.9L Cummins

Finding the right replacement engine determines the long-term success and satisfaction with your completed engine swap project. Research reputable suppliers offering a quality 5.9 Cummins motor for sale to ensure you receive a reliable powerplant. Consider factors like mileage, maintenance history, accessories included, and warranty coverage when evaluating potential replacement engines. Salvage yards, specialty diesel shops, and online marketplaces provide various options for sourcing your replacement Cummins engine.

Engine Mount and Bracket Modifications

Proper engine mounting ensures your 5.9L Cummins sits securely and aligns correctly with drivetrain components. Original equipment mounts may not accommodate the diesel engine's different dimensions, weight distribution, and mounting point locations. Custom fabrication or aftermarket mount kits provide solutions for securing the engine while maintaining proper alignment. Verify that your chosen mounting solution supports the engine's weight and withstands the torque generated during operation.

Cooling System Requirements and Upgrades

The 5.9L Cummins generates substantial heat that requires an adequate cooling system to maintain optimal operating temperatures. Diesel engines typically require larger radiators, higher-capacity water pumps, and upgraded cooling fans compared to gasoline engines. Consider the coolant capacity, thermostat rating, and cooling system pressure requirements when planning your installation. Upgrading cooling components prevents overheating issues and ensures reliable operation under various driving conditions and load situations.

Fuel System Integration and Setup

Integrating the fuel system properly ensures your 5.9L Cummins receives an adequate fuel supply for optimal performance and reliability. Diesel fuel systems operate at higher pressures than gasoline systems, requiring compatible fuel lines, filters, and pumps. Install a fuel water separator to protect the injection system from contaminated fuel that could damage expensive components. Verify that your fuel tank, sending unit, and gauge cluster accommodate diesel fuel system requirements and pressure specifications.

Exhaust System Configuration

The exhaust system must accommodate the diesel engine's different exhaust characteristics, including increased backpressure and emission requirements. Diesel engines produce different exhaust temperatures and flow rates compared to gasoline engines, requiring appropriate pipe sizing. Consider turbocharger integration, exhaust brake compatibility, and local emission regulations when designing your exhaust system. A proper exhaust system design maximizes performance while meeting legal requirements in your area.

Testing and Break-in Procedures

Initial startup and break-in procedures protect your investment and ensure long-term reliability from your swapped engine. Check all fluid levels, verify electrical connections, and inspect for leaks before attempting to start the engine. Follow manufacturer recommendations for break-in oil, operating temperatures, and load restrictions during the initial operating period. Monitor engine parameters closely during the first several hundred miles to identify potential issues early.

Performance Tuning and Optimization

Fine-tuning your 5.9L Cummins maximizes performance potential while maintaining reliability for daily driving or work applications. Engine management systems require calibration to optimize fuel delivery, timing, and turbocharger operation for your specific application. Consider professional tuning services that specialize in Cummins diesel engines to achieve optimal results safely. Proper tuning enhances fuel economy, power output, and the overall driving experience while protecting engine components from damage.

Final Inspection and Road Testing

A comprehensive final inspection ensures all systems function properly before returning your vehicle to regular service conditions. Verify all connections, check fluid levels, and inspect for leaks that may have developed during the installation process. Conduct thorough road testing under various conditions to evaluate performance, shifting quality, and overall system integration. Address any issues discovered during testing before considering your engine swap project complete and successful.

A 5.9L Cummins engine swap represents a significant undertaking that rewards careful planning and execution with years of reliable service. Proper preparation, quality components, and attention to detail ensure your project meets expectations for performance and dependability. Ready to upgrade your build? Shop at Blessed Performance today for the parts you need to get it done right.