Rebuilding a 2019 Powerstroke: A Complete Guide

Estimated 0 min read

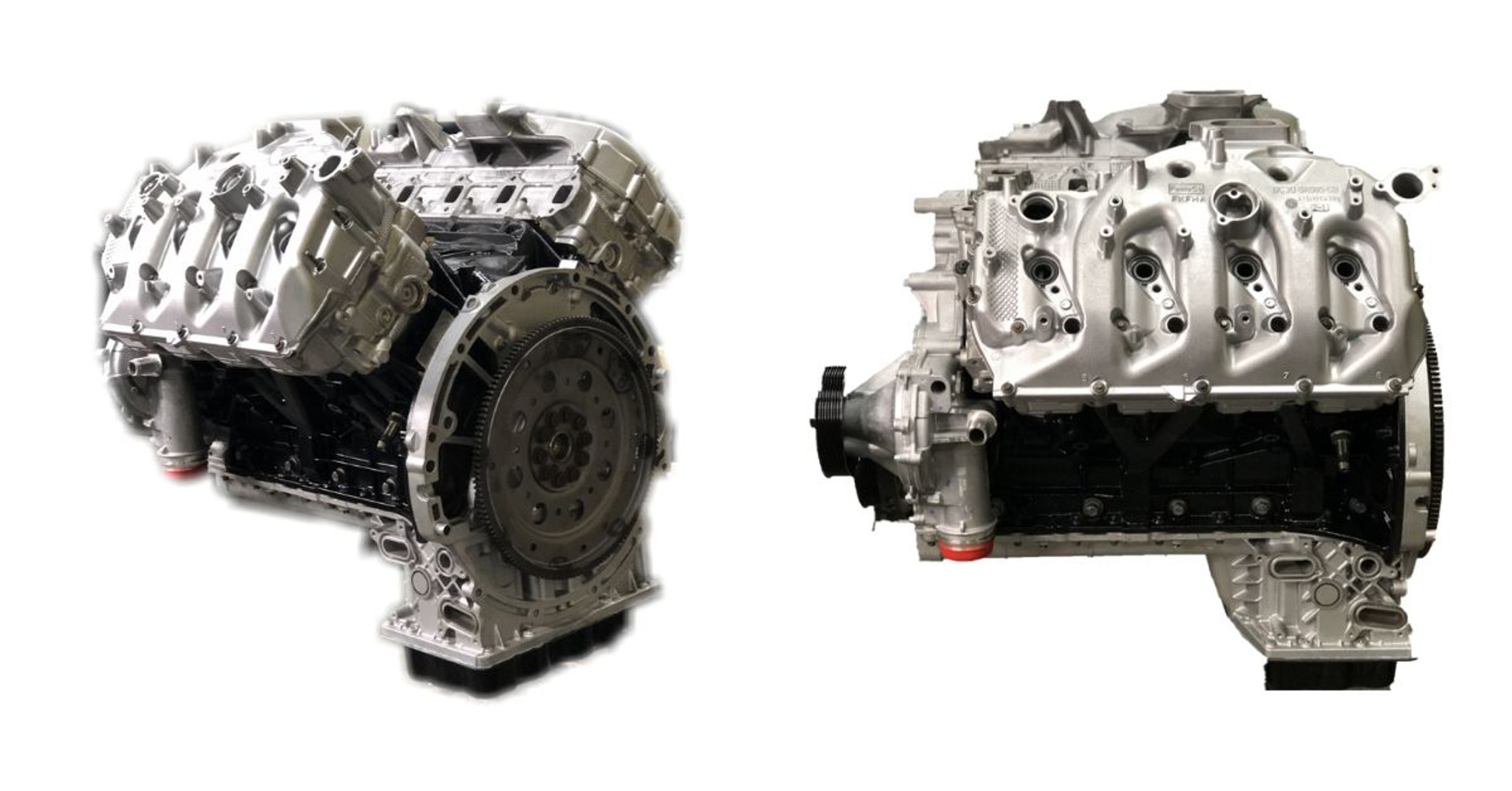

Rebuilding a 2019 Powerstroke engine is a project that requires careful planning and technical expertise. The 6.7L Powerstroke diesel engine powers many Ford Super Duty trucks and demands respect during the rebuild process. Understanding the complexities involved helps truck owners make informed decisions about their engine's future. This comprehensive guide walks you through every aspect of the process from start to finish, serving as a complete guide to rebuild a 2019 Powerstroke engine.

Understanding Your 2019 Powerstroke Engine

The 2019 Ford 6.7L Powerstroke engine incorporates several improvements over earlier generations of this powerplant design. Ford engineers enhanced the turbocharger system, fuel injection components, and emission control systems for better performance and reliability. The engine produces impressive torque figures while meeting strict emission standards through advanced aftertreatment systems. These technological advances create both opportunities and challenges during the rebuild process that require careful consideration.

Signs Your Powerstroke Needs Rebuilding

Several warning signs indicate your 2019 Powerstroke engine may require a complete rebuild rather than simple repairs. Excessive blue or white smoke from the exhaust pipe often signals worn piston rings or damaged cylinder walls. Metal shavings in the oil pan suggest bearing wear or other internal component failure requiring immediate attention. Persistent knocking sounds, loss of power, or excessive oil consumption also point toward major internal engine problems.

Planning Your Powerstroke Rebuild Project

Successful engine rebuilds begin with thorough planning that addresses timeline, budget, and workspace requirements for the project ahead. Professional rebuild shops typically require four to six weeks to complete a comprehensive 6.7L Powerstroke rebuild project. Home mechanics should expect longer timelines due to limited experience and the need to thoroughly research procedures. Creating a detailed checklist helps ensure no critical steps get overlooked during the complex rebuild process.

Essential Tools and Equipment Needed

Rebuilding a 2019 Powerstroke engine requires specialized tools that most home mechanics don't typically own or use. Engine hoists, transmission jacks, and precision measuring instruments become essential for proper disassembly and reassembly procedures. Torque specifications for critical components require calibrated torque wrenches that can handle the substantial forces involved. Professional-grade cleaning equipment ensures that all components meet the cleanliness standards necessary for successful engine rebuilds.

Disassembly Process and Component Inspection

The disassembly process follows a specific sequence that preserves component integrity while allowing thorough inspection of all parts. Begin by draining all fluids and removing external components, such as the turbocharger, intercooler, and fuel system components. Document the location and orientation of each element with photographs to simplify the reassembly process later. Careful labeling of bolts and small parts prevents confusion during reassembly at the final stage.

Evaluating Core Components for Reuse

A professional inspection determines which components can be safely reused and which need to be replaced during the rebuild process. Cylinder walls require a precise measurement to determine if boring or honing will restore the proper surface finish and dimensions. Crankshafts require magnaflux testing to detect hairline cracks that could lead to catastrophic failures in rebuilt engines. If major components prove unusable, finding a complete 6.7 Powerstroke engine for sale might provide better value than extensive machining work.

Machining Work and Professional Services

Most Powerstroke rebuilds require professional machining services that exceed the capabilities of typical home workshops or garages. Cylinder boring, crankshaft grinding, and deck surfacing demand specialized equipment operated by experienced technicians with proper training. Valve guide replacement and seat cutting require precision work that directly affects engine performance and longevity. Research local machine shops thoroughly and verify their experience with Ford diesel engines before committing to services.

Selecting Quality Replacement Parts

Component quality has a significant impact on the longevity and performance of your rebuilt 2019 Powerstroke engine throughout its service life. OEM Ford parts provide guaranteed compatibility and reliability, but often cost significantly more than aftermarket alternatives. Premium aftermarket brands like Mahle, Federal Mogul, and Clevite offer excellent quality at more reasonable price points. Avoid bargain-basement parts that compromise reliability and potentially cause a premature failure of your expensive rebuild investment.

Assembly Process and Critical Specifications

Engine assembly requires meticulous attention to torque specifications, clearances, and assembly procedures outlined in Ford service documentation. Bearing clearances must fall within precise tolerances to ensure proper oil pressure and component longevity throughout operation. Ring gap specifications and installation procedures directly affect compression, oil consumption, and overall engine performance in service. Take time to verify each specification rather than rushing through assembly procedures that affect long-term reliability.

Break-in Procedures for Rebuilt Engines

Proper break-in procedures ensure optimal ring seating and bearing wear patterns that maximize the lifespan of rebuilt engines. Initial startup requires careful monitoring of oil pressure, coolant temperature, and any unusual noises that indicate assembly problems. Varying engine speeds during the first several hundred miles promotes proper ring seating without causing excessive wear. Avoid sustained high loads or constant speeds that prevent proper component seating during this critical period.

Cost Considerations and Budgeting

Professional Powerstroke rebuilds typically cost between $8,000 and $15,000, depending on the condition of the components and the required machining work. Parts alone often exceed $4,000 when including pistons, rings, bearings, gaskets, and other essential elements for complete rebuilds. Machine work adds substantial costs that vary based on component conditions and local shop rates in different areas. Budget an additional 20% above initial estimates to cover unexpected issues discovered during disassembly and inspection procedures.

For example, a shop may quote $9,500 for a complete rebuild, but during teardown, they discover a cracked cylinder head or worn crankshaft journals that require a replacement or extra machining. Those added repairs could quickly raise the final bill by $2,000 or more, pushing the total cost closer to $12,000. Planning for these possibilities upfront helps avoid financial surprises and ensures you’re prepared for a thorough, reliable rebuild that extends the life of your Powerstroke engine.

When To Consider Professional Help

Complex emission control systems and advanced fuel injection components make 2019 Powerstroke rebuilds challenging for inexperienced mechanics. Professional shops typically have diagnostic equipment, offer technical training, and provide warranty support that home mechanics often cannot afford or access. Labor warranties protect your investment against assembly errors that could cause expensive damage to rebuilt engines. Consider professional services if you lack experience, the proper tools, or an adequate workspace for this complex project.

Maximizing Your Rebuilt Engine's Lifespan

Proper maintenance practices extend the service life of rebuilt Powerstroke engines far beyond their original design expectations. Regular oil changes using high-quality diesel engine oil prevent premature bearing wear and maintain proper lubrication systems. Fuel system maintenance, including filter changes and water separation, helps avoid damage to the injection system from contaminated fuel supplies. Following manufacturer recommendations for service intervals ensures optimal performance and reliability from your rebuilt engine investment.

Rebuilding a 2019 Power Stroke engine requires careful planning, high-quality components, and meticulous attention to detail throughout every step. Whether you tackle the project yourself or hire professionals, understanding the process helps ensure successful results. The investment in a proper rebuild provides years of reliable service and maintains your truck's value. Take time to research thoroughly and choose quality components that justify the substantial investment required for success.