The History and Evolution of Powerstroke Engines

Estimated 0 min read

Ford’s Powerstroke diesel engine has powered heavy-duty trucks for over three decades, becoming synonymous with capability and endurance. From its humble beginnings in the mid-1990s to the sophisticated powerplants of today, the Powerstroke line represents one of the most significant developments in diesel technology. Understanding the history and evolution of Powerstroke engines helps truck owners appreciate the engineering innovations that have shaped modern diesel performance.

The Powerstroke story spans multiple generations, each bringing unique improvements while facing distinct challenges. Companies like Blessed Performance have played a crucial role in keeping older Powerstroke engines running strong through expert refurbishment and optimization services.

The Foundation: 7.3L Powerstroke (1994-2003)

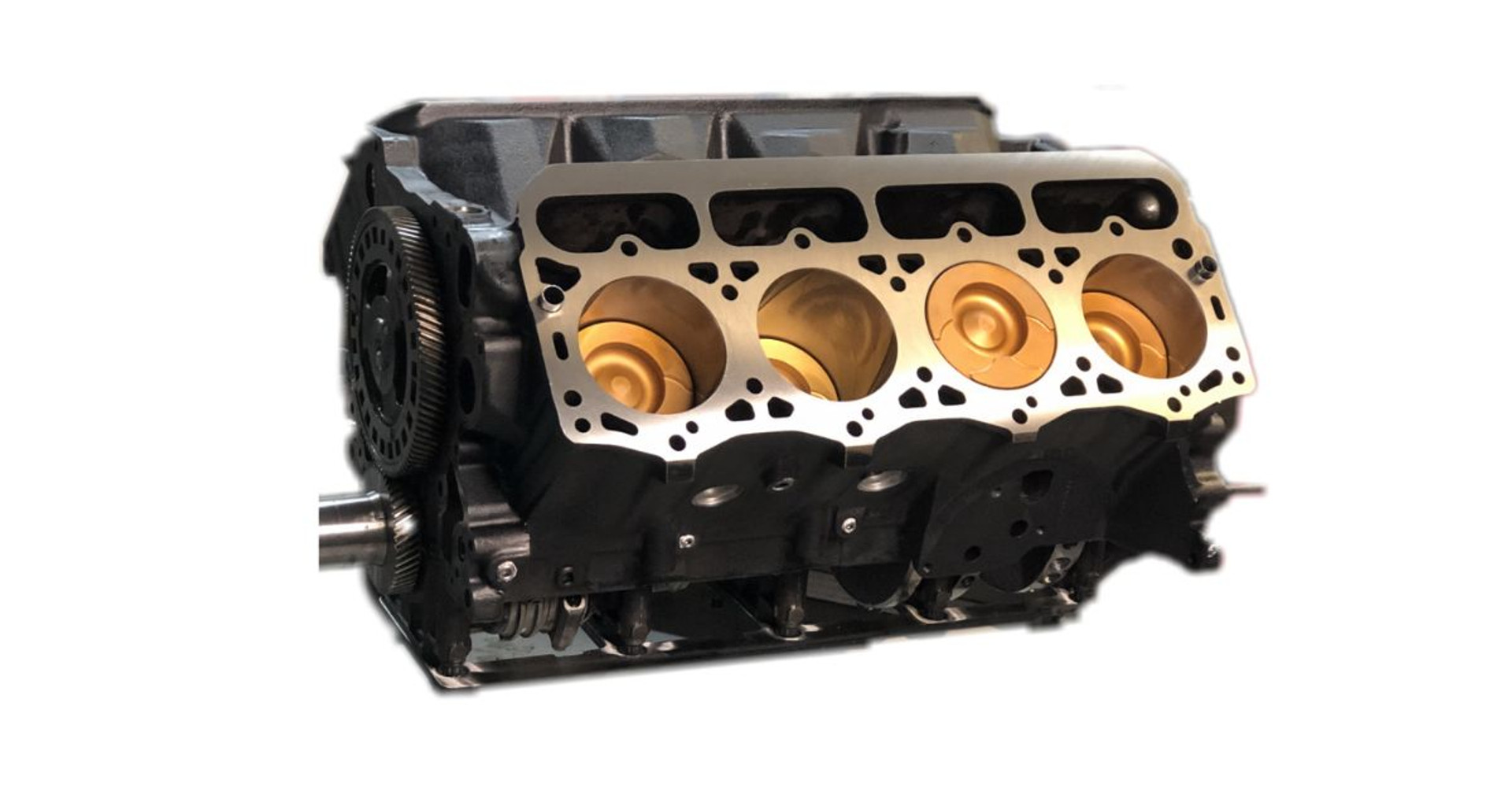

Ford introduced the 7.3L Powerstroke in 1994, marking a revolutionary shift in diesel truck technology. This naturally aspirated engine displaced 444 cubic inches and delivered a respectable 210 horsepower with 425 lb-ft of torque in its early years. By 2003, power output had climbed to 250 horsepower and 525 lb-ft of torque, showcasing steady improvements throughout its production run.

International Navistar developed the 7.3L engine specifically for Ford’s Super Duty lineup. The engine featured a cast-iron block construction with wet cylinder sleeves, providing exceptional durability. Its indirect injection system used a precombustion chamber design, resulting in smoother, quieter operation than previous diesel engines.

The 7.3L earned a legendary reputation for reliability, but it wasn’t without challenges. Common issues included electronic failures, particularly with the IDM (Injector Driver Module) module overheating. Turbocharger problems also plagued some units, especially those subjected to heavy towing or high-mileage use. Despite these concerns, many 7.3L engines exceeded 300,000 miles with proper maintenance.

Blessed Performance recognized the enduring value of these engines and began offering comprehensive refurbishment services. Their 7.3 Powerstroke crate motor program addresses common failure points while optimizing performance beyond factory specifications. Each refurbished engine undergoes rigorous testing to deliver reliability that often surpasses the original powerplant.

The Problematic 6.0L Era (2003-2007)

Ford replaced the beloved 7.3L with the 6.0L Powerstroke in 2003, hoping to improve power output and emissions compliance. The new engine produced 325 horsepower and 560 lb-ft of torque while incorporating advanced features like variable geometry turbocharging and exhaust gas recirculation (EGR).

The 6.0L represented a significant technological leap, featuring low pressure common rail fuel and oil to provide high pressure fuel injection via HEUI Injection and improved combustion efficiency. Engineers designed the engine to meet stricter emissions standards while delivering more power per liter than its predecessor. The variable geometry turbocharger provided better boost control across the RPM range, resulting in improved throttle response and reduced turbo lag.

Unfortunately, the 6.0L became notorious for reliability problems that frustrated owners and dealers alike. Head gasket failures plagued the engine due to inadequate head bolt torque specifications and insufficient cooling system design. The EGR cooler frequently failed, allowing coolant to enter the intake system and potentially causing catastrophic engine damage. Oil cooler problems and turbocharger failures added to the engine’s problematic reputation.

These issues stemmed partly from the engine’s transition period, as Ford rushed to meet new emissions regulations while maintaining competitive power levels. The 6.0L’s problems were so widespread that Ford eventually extended warranties and implemented multiple technical service bulletins to address common failures.

The Short-Lived 6.4L Powerstroke (2008-2010)

Ford introduced the 6.4L Powerstroke in 2008, hoping to redeem the brand’s reputation after the 6.0L’s troubles. This engine featured twin turbochargers in a compound configuration, with a smaller high-pressure turbo feeding a larger low-pressure unit. The setup delivered impressive power numbers: 350 horsepower and 650 lb-ft of torque.

The 6.4L incorporated several advanced technologies, including piezoelectric fuel injectors and a sophisticated exhaust aftertreatment system. The diesel particulate filter (DPF) and selective catalytic reduction (SCR) system helped the engine meet stringent emissions requirements while maintaining competitive performance levels.

Despite these improvements, the 6.4L faced its own set of challenges. The complex emissions equipment proved problematic, with DPF regeneration issues causing reduced fuel economy and potential engine damage. The compound turbocharger system, while effective, created additional complexity and possible failure points. Many owners reported shorter engine life than with earlier Powerstroke generations.

Ford discontinued the 6.4L after just three years, recognizing that the engine failed to meet long-term reliability expectations. The brief production run means fewer of these engines remain in service today, but those that survive often require specialized knowledge for proper maintenance and repair.

The Modern 6.7L Powerstroke (2011-Present)

Learning from previous missteps, Ford developed the 6.7L Powerstroke entirely in-house, marking the first time the company had complete control over its diesel engine design. Launched in 2011, the 6.7L represented a fresh start for the Powerstroke brand, incorporating lessons learned from earlier generations.

The 6.7L features a compacted graphite iron (CGI) block construction that provides superior strength compared to traditional cast iron while remaining lighter than steel. The engine uses a single variable geometry turbocharger with an advanced wastegate design for precise boost control. Power output has steadily increased throughout the engine’s production run, with current versions producing over 475 horsepower and 1,050 lb-ft of torque.

Ford addressed previous reliability concerns by implementing robust cooling systems, improved head gasket designs, and better quality control throughout manufacturing. The engine features a sophisticated fuel system with solenoid-operated injectors capable of multiple injection events per combustion cycle. This technology improves fuel efficiency while reducing noise and emissions.

The 6.7L has proven far more reliable than its immediate predecessors, with many examples approaching high mileage without major issues. Ford continues refining the engine with regular updates that address minor concerns and improve overall performance. The engine’s modular design makes maintenance and repair easier than with earlier Powerstroke generations.

Technical Evolution and Innovation

Each Powerstroke generation brought significant technological advances that advanced diesel performance. The progression from mechanical injection to electronic control systems revolutionized the precision and timing of fuel delivery. Turbocharging technology evolved from simple fixed-geometry units to sophisticated variable systems that optimize boost across all operating conditions.

Emissions control technology represents perhaps the most dramatic change throughout Powerstroke’s evolution. Early engines relied primarily on combustion optimization to meet regulations, while modern versions incorporate complex aftertreatment systems including DPFs, SCR systems, and exhaust gas recirculation. These systems successfully reduce harmful emissions but add complexity that affects maintenance requirements and long-term durability.

Fuel injection technology has undergone continuous refinement, moving from indirect injection chambers to high-pressure common rail systems. Modern piezoelectric injectors operate at pressures exceeding 30,000 PSI, enabling precise fuel metering and multiple injection events that improve combustion efficiency and reduce noise.

Looking Forward

The Powerstroke story continues evolving as Ford adapts to changing emissions regulations and customer expectations. Future developments will likely focus on improving fuel efficiency while maintaining the power and capability that define the Powerstroke brand. Hybrid technology integration and alternative-fuel compatibility may shape the next chapter of Powerstroke’s evolution.

For owners of existing Powerstroke engines, understanding this rich history helps inform maintenance decisions and modification choices. Whether maintaining a cherished 7.3L or upgrading to a modern 6.7L, knowledge of the engine’s development provides valuable context for making sound decisions.

Blessed Performance continues supporting Powerstroke owners across all generations, offering everything from complete crate engines to specialized repair services. Their expertise spans the entire Powerstroke timeline, providing valuable resources for keeping these capable engines running strong for years to come.

Contact Blessed Performance today to learn more about our Powerstroke engine services and how they can help optimize your diesel truck’s performance and reliability.